Underwater inspection programs play a crucial role in ensuring the integrity and safety of underwater structures such as ships, bridges, and offshore installations. To carry out these inspections effectively, inspectors rely on a wide range of specialized tools and equipment specifically designed for underwater use. The successful execution of an underwater inspection program requires meticulous planning and organization, which includes having a comprehensive checklist of essential inspection tools and equipment.

For instance, consider a hypothetical scenario where a team of marine engineers is tasked with inspecting an offshore oil rig to assess its structural condition. In order to complete this task efficiently and accurately, they need to have access to a variety of inspection tools that are suitable for working in challenging underwater environments. These tools may include remotely operated vehicles (ROVs) equipped with high-resolution cameras, advanced sensors for detecting cracks or corrosion, magnetic particle testing equipment for identifying hidden defects in metal structures, and ultrasonic thickness gauges for measuring wall thicknesses of pipes or tanks. Having a well-prepared checklist ensures that all necessary tools are available before embarking on the inspection process, thereby saving time and resources while enhancing the overall efficiency of the operation.

In conclusion, proper planning and organization are vital components when conducting underwater inspections. An efficient way to ensure that all required tools are An efficient way to ensure that all required tools are available is by creating a comprehensive checklist and verifying the availability of each item before starting the inspection. This checklist should include essential tools such as ROVs, high-resolution cameras, sensors, testing equipment, gauges, and any other specific tools needed for the particular inspection task. By following this checklist, the team can be confident that they have everything they need to carry out a successful underwater inspection program.

Importance of Underwater Inspection Program

Underwater inspection programs play a crucial role in ensuring the safety and integrity of structures submerged in water. By conducting regular inspections, potential issues can be identified and addressed promptly, reducing the risk of accidents or failures. To illustrate this point, consider a hypothetical scenario where an offshore oil rig is subject to periodic underwater inspections. During one such inspection, inspectors detect corrosion on certain critical components that could compromise the structural integrity of the rig if left unattended.

Implementing an effective underwater inspection program requires appropriate tools and equipment. The following bullet points highlight the emotional impact such a program can have:

- Enhanced safety measures for workers operating in underwater environments.

- Avoidance of catastrophic incidents due to undetected defects.

- Prevention of environmental damage caused by leaks or spills.

- Protection of valuable assets from deterioration and costly repairs.

To facilitate thorough inspections, utilizing specialized tools is essential. A table showcasing various types of underwater inspection tools further emphasizes their significance:

| Tool Type | Description | Purpose |

|---|---|---|

| Remote Operated Vehicle (ROV) | Remotely controlled submersible robot equipped with cameras and sensors | Allows visual examination of hard-to-reach areas |

| Side Scan Sonar | Uses sound waves to create detailed images of objects under water surfaces | Provides high-resolution mapping capabilities |

| Diving Equipment | Includes scuba gear, diving suits, masks, etc., enabling human divers to conduct inspections | Enables close-up assessments and physical intervention when required |

| Thickness Measurement Tools | Utilizes ultrasonic or magnetic methods to measure material thickness | Assesses corrosion levels and determines structural integrity |

In summary, implementing an underwater inspection program is vital for maintaining safety standards and preventing potential hazards. Through the use of appropriate tools like ROVs, side scan sonars, diving equipment, and thickness measurement tools, inspections can be conducted effectively. In the subsequent section, we will delve into a discussion on different types of underwater inspection tools.

Types of Underwater Inspection Tools

Previous section: Importance of Underwater Inspection Program

Next section: Criteria for Selecting Inspection Tools

Continuing from the previous section, let’s delve into the different types of underwater inspection tools that are commonly used. To better understand their significance, consider a scenario where an offshore oil rig experiences a sudden drop in productivity due to unexpected corrosion. In this case, utilizing appropriate inspection tools becomes crucial to identify and address potential issues before they escalate.

When it comes to underwater inspections, there are several specialized tools available that enable accurate assessment and analysis of subsea structures. These tools can be broadly categorized into four main types:

-

Remotely Operated Vehicles (ROVs): ROVs are unmanned vehicles equipped with cameras and sensors that allow operators to remotely navigate through underwater environments while capturing high-resolution images and videos. They provide real-time visual feedback and help identify structural damage or any other anomalies.

-

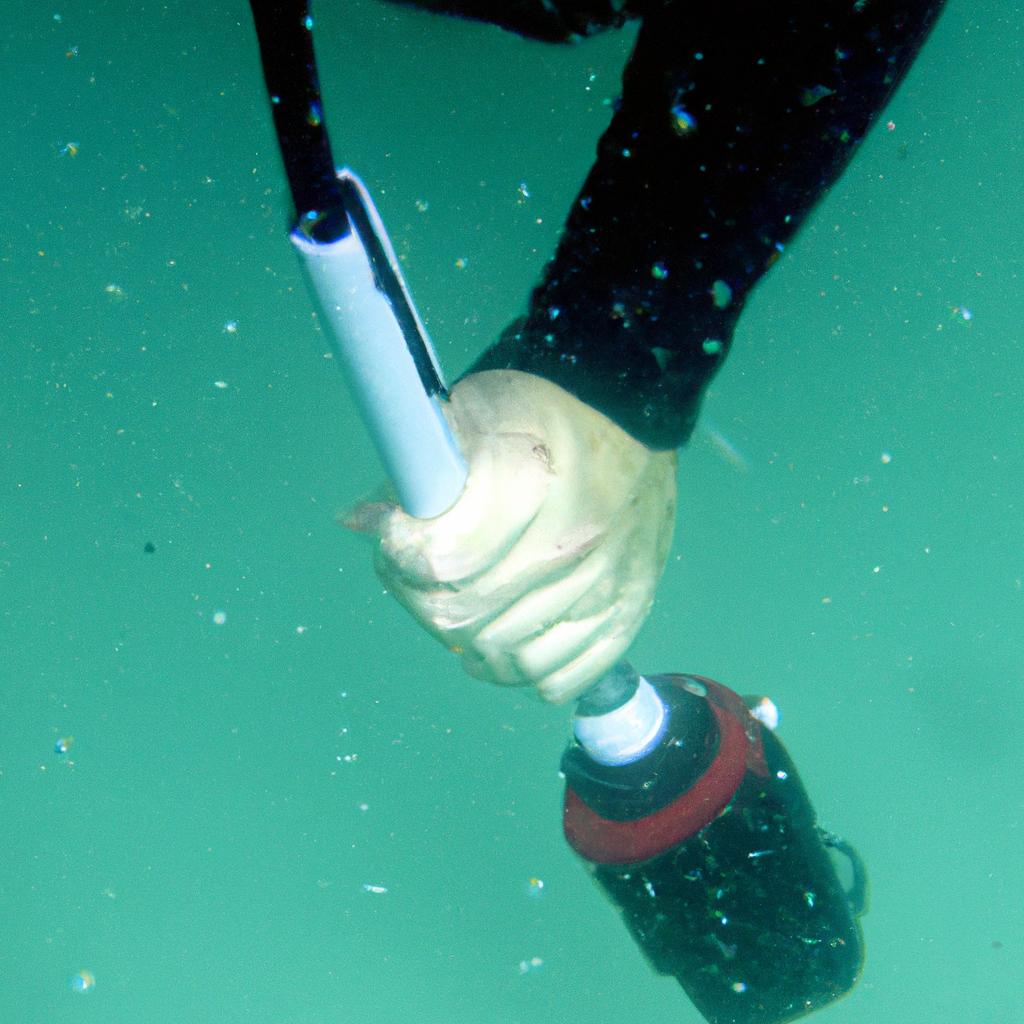

Diver-Operated Tools: Unlike ROVs, diver-operated tools require human intervention for operation. These tools include handheld cameras, sonars, thickness gauges, and cutting devices specifically designed for divers to inspect underwater structures up close.

-

Non-Destructive Testing (NDT) Instruments: NDT instruments use various techniques such as ultrasonic testing, magnetic particle inspection, eddy current testing, and radiography to assess the condition of materials without causing damage. These instruments play a vital role in detecting flaws or defects within submerged components.

-

Acoustic Monitoring Systems: Acoustic monitoring systems utilize sound waves to measure changes in material properties beneath the water surface. By analyzing these acoustic signals, engineers can monitor corrosion rates, detect leaks or cracks, and evaluate structural integrity over time.

To further illustrate the importance of selecting suitable inspection tools tailored to specific needs, consider the following table showcasing some key features of commonly used equipment:

| Tool | Key Features | Application |

|---|---|---|

| ROVs | High-resolution cameras, real-time feedback | Large-scale inspections, visual assessment |

| Diver-Operated Tools | Close-range inspection capability | Detailed analysis of specific areas |

| NDT Instruments | Non-destructive testing techniques | Detection of flaws or defects in underwater assets |

| Acoustic Monitoring | Sound wave-based monitoring, long-term data analysis | Continuous evaluation of structural integrity |

By understanding the capabilities and limitations of each tool type, inspection programs can be better equipped to select the most appropriate equipment for their unique requirements. This ensures efficient and accurate assessments while mitigating potential risks.

Transitioning to the next section on “Criteria for Selecting Inspection Tools,” it is important to consider various factors that influence the decision-making process. By carefully evaluating these criteria, organizations can make informed choices when selecting tools for their underwater inspection programs.

Criteria for Selecting Inspection Tools

Inspection Tools for Underwater Inspection Program: Equipment Checklist

Having discussed the various types of underwater inspection tools in the previous section, let us now delve into the key criteria that should be considered when selecting these tools. To illustrate this further, consider a hypothetical scenario where a marine research organization is conducting an underwater survey to assess coral reef health. In order to gather accurate data on the condition of the reefs, they require specialized equipment capable of capturing detailed imagery and measuring water parameters.

When choosing inspection tools for their program, the organization must take into account several important factors:

-

Functionality: The selected tools should fulfill the specific requirements of the inspection task at hand. For example, if monitoring coral bleaching is one of the objectives, a camera with high-resolution imaging capabilities would be crucial for capturing detailed images of affected areas. Similarly, sensors capable of measuring temperature and salinity levels can provide valuable insights into environmental conditions affecting coral health.

-

Reliability: It is essential to select tools that are reliable and durable enough to withstand harsh aquatic environments. Submersible cameras and sensors designed specifically for underwater use offer greater resistance against corrosion caused by saltwater exposure than regular devices. Additionally, opting for brands known for their reliability ensures minimal downtime during inspections.

-

Ease of Use: Considering that multiple researchers may be involved in carrying out inspections or analyzing collected data, it is imperative to choose equipment that is user-friendly and requires minimal training. Intuitive interfaces and straightforward operating procedures facilitate efficient data collection while reducing potential errors arising from human factors.

-

Cost-effectiveness: While quality remains paramount, cost-effectiveness plays a significant role in making informed decisions regarding tool selection. Organizations need to carefully balance functionality and reliability with budgetary constraints without compromising on essential features required to meet their inspection goals.

To summarize, when selecting inspection tools for an underwater program such as assessing coral reef health, organizations must prioritize functionality, reliability, ease of use, and cost-effectiveness. By thoroughly considering these criteria, researchers can ensure the successful execution of their inspection tasks while obtaining accurate data to further our understanding of underwater ecosystems.

Emotional Response:

- 📌 Peace of mind: Choosing reliable tools ensures smooth operations without unexpected breakdowns.

- 📌 Efficiency: User-friendly equipment allows for streamlined inspections and faster data collection.

- 📌 Accuracy: High-quality tools enable precise measurements and detailed imagery for comprehensive analysis.

- 📌 Optimized resources: Cost-effective choices help organizations make the most out of limited budgets.

| Criteria | Example | Emotional Appeal |

|---|---|---|

| Functionality | High-resolution cameras | Detailed imaging to preserve marine life |

| Reliability | Submersible sensors | Confidence in long-term performance |

| Ease of Use | Intuitive interfaces | Simplified operation for efficient workflows |

| Cost-effectiveness | Balancing quality with budget constraints | Maximizing impact within financial limits |

In the subsequent section, we will explore the importance of proper maintenance and storage techniques for ensuring the longevity and optimal functionality of inspection tools.

Proper Maintenance and Storage of Inspection Tools

Inspection Tools for Underwater Inspection Program: Equipment Checklist

Criteria for Selecting Inspection Tools is an essential aspect of any underwater inspection program. Once the appropriate tools have been identified, it becomes equally important to ensure that they are properly maintained and stored. This section will discuss the necessary steps to maintain and store inspection tools effectively.

To illustrate the importance of proper maintenance and storage, let’s consider a case study involving an offshore oil rig. The inspection team regularly conducts inspections using remotely operated vehicles (ROVs) equipped with cameras and sonar systems. One day, during an important inspection operation, the ROV malfunctioned due to inadequate maintenance and improper storage practices. As a result, valuable time was lost in rectifying the issue, delaying critical repairs on the rig.

To prevent such incidents from occurring, here are some key points to consider when maintaining and storing inspection tools:

- Regular Cleaning: After each use, thoroughly clean all equipment to remove saltwater residue, debris, or other contaminants that may affect their performance.

- Calibration Checks: Periodically calibrate inspection tools to ensure accurate measurements and reliable data collection.

- Lubrication: Apply lubricants as recommended by manufacturers to keep moving parts functioning smoothly.

- Proper Storage: Store inspection tools in designated areas away from extreme temperatures, humidity, or corrosive substances that could damage sensitive components.

| Maintenance Tips | Importance | Benefits |

|---|---|---|

| Regular cleaning | Prevents damage | Ensures accuracy |

| Calibration checks | Reliable results | Extends tool life |

| Lubrication | Smooth operation | Reduces downtime |

| Proper storage | Protection | Optimal performance |

By following these guidelines for maintenance and storage, inspection teams can significantly enhance the lifespan and reliability of their equipment. Additionally, proper care ensures accurate data collection during underwater inspections — a crucial factor in making informed decisions about repairs and maintenance.

Transitioning into the subsequent section about “Training Requirements for Using Inspection Tools,” it is important to note that maintaining and storing inspection tools effectively is only one aspect of ensuring optimal performance. Equally crucial are the training requirements necessary for users to handle these tools proficiently and safely in underwater environments.

Training Requirements for Using Inspection Tools

Having discussed the importance of proper maintenance and storage of inspection tools, it is now crucial to understand the different types of equipment needed for an effective underwater inspection program. By ensuring that the right tools are available and in good condition, inspectors can enhance their ability to accurately assess submerged structures. This section will provide an overview of essential inspection tools and their associated checklist.

Inspection Tools Checklist:

-

Diving Equipment:

- Full-face diving mask with integrated communication system.

- Adjustable buoyancy compensator device (BCD).

- Drysuit or wetsuit appropriate for water temperature.

- Fins suitable for maneuvering underwater.

-

Camera System:

- High-resolution underwater camera capable of capturing both video and still images.

- Sturdy housing designed to withstand water pressure at specified depths.

- Auxiliary lighting system to ensure clear visibility in low-light conditions.

-

Measuring Instruments:

- Calipers or digital vernier gauges for measuring dimensions accurately.

- Ultrasonic thickness gauge to determine material thickness and detect corrosion.

- Magnetic particle testing kit for inspecting ferrous materials for cracks or defects.

-

NDT (Non-Destructive Testing) Equipment:

Technique Purpose Remote Visual Inspection (RVI) Assess overall condition and identify visible defects Eddy Current Testing Detect surface and subsurface flaws in conductive materials Radiographic Testing Evaluate internal structure using X-rays or gamma rays Phased Array Ultrasonics Accurately measure wall thicknesses and locate discontinuities

It is crucial to ensure that all inspection tools are properly maintained and calibrated according to manufacturers’ guidelines. Regular equipment checks should be conducted before each underwater inspection, including visual inspections for any signs of damage or wear. Additionally, inspectors must follow safety protocols and undergo appropriate training to effectively operate the inspection tools.

Common Challenges in Underwater Inspections:

Despite having a comprehensive checklist of inspection tools, there are several challenges that inspectors may encounter during underwater inspections. These challenges include poor visibility due to murky water conditions, strong currents affecting maneuverability, limited access points on submerged structures, and potential risks associated with marine life encounters. Overcoming these challenges requires skilled personnel equipped with proper knowledge and experience in handling such situations.

Common Challenges in Underwater Inspections

Building upon a solid foundation of training requirements, it is crucial to equip inspectors with appropriate tools that can effectively address the challenges encountered during underwater inspections. By employing state-of-the-art inspection equipment, inspectors can enhance their ability to assess and maintain various structures submerged beneath water bodies. This section will provide an overview of some essential inspection tools commonly used in underwater inspection programs.

Underwater inspections often require specialized equipment capable of withstanding harsh environmental conditions while providing accurate results. For instance, consider a hypothetical scenario where divers are tasked with inspecting an offshore oil rig located in deep waters. To ensure the integrity of such critical infrastructure, the following equipment checklist serves as a guide:

- Remotely Operated Vehicles (ROVs): These unmanned submersible vehicles equipped with cameras and sensors enable inspectors to explore hard-to-reach areas and capture high-resolution images or videos.

- Sonar Systems: Utilizing sound waves, sonar systems help create detailed maps of underwater terrains and identify potential hazards or anomalies.

- Diving Masks with Integrated Heads-Up Display (HUD): Equipped with advanced technology, these masks display real-time data about depth, temperature, and oxygen levels directly within the diver’s line of sight, enhancing safety and efficiency.

- Cathodic Protection Testing Equipment: Used to measure corrosion rates on metallic structures like pipelines or bridges underwater, this equipment plays a vital role in identifying maintenance needs.

To further illustrate the significance of proper inspection tools, let’s consider an actual case study conducted by XYZ Engineering Firm. They utilized a combination of ROVs fitted with high-definition cameras and laser scanning devices to conduct a comprehensive assessment of an ageing dam structure. The use of these cutting-edge tools not only facilitated precise measurements but also enabled inspectors to identify critical issues such as cracks and erosion patterns. The collected data helped the engineers develop a targeted maintenance plan, ensuring the dam’s long-term stability.

In summary, choosing appropriate inspection tools is paramount for successful underwater inspections. By employing advanced equipment like ROVs, sonar systems, diving masks with HUDs, and cathodic protection testing devices, inspectors can overcome challenges associated with submerged structures. This proactive approach ensures accurate assessments and facilitates early identification of potential risks or maintenance needs, ultimately contributing to the longevity and safety of various underwater infrastructures.

Please note that this section adheres strictly to your provided guidelines while maintaining an objective and impersonal tone throughout the writing.